Project Overview: The 6×6 Camper by FGS Composites

Meet the 6×6 Camper, a cutting-edge off-road vehicle that combines advanced engineering with rugged durability. Designed and built by FGS Composites, we at CFI are proud to have contributed to this project by supplying high-quality composite materials and providing expert consultation on the best products to use. This collaboration showcases the latest in composite materials and modular design, resulting in a vehicle that’s as tough as it is innovative.

Meet the 6×6 Camper, a cutting-edge off-road vehicle that combines advanced engineering with rugged durability. Designed and built by FGS Composites, we at CFI are proud to have contributed to this project by supplying high-quality composite materials and providing expert consultation on the best products to use. This collaboration showcases the latest in composite materials and modular design, resulting in a vehicle that’s as tough as it is innovative.

FGS Composites: FGS is a Queensland-based specialist composite and engineering company that builds extreme off-road campers. It is headed by URS Kueng and his highly skilled team of tradespeople. They manufacture fully onsite and provide turn-key solutions for their clients.

Project Scope and Duration

The 6×6 Camper project spanned 10 months, from initial discussions to the final build. This timeframe included extensive planning, design, and collaboration among various teams to ensure every detail met the highest standards.

Materials and Techniques

The construction of the 6×6 Camper utilised top-tier materials and advanced manufacturing techniques:

- Armacell PET Strut Cores: These revolutionary recycled cores provide excellent acoustic and thermal insulation, contributing to the vehicle’s eco-friendly profile – PET Armacell struct 40+50mm and 50mm Honeycomb

- CFI Gun Roving and E-Glass Fabrics: These high-strength fabrics were used to create robust FRP components – Gun Roving, 600 + 1200gr DB Basalt Fibre

- CDR Resins and Gelcoats: Applied using VIP Infusion processing, these materials ensure superior strength and durability – Iso Pool Gelcoat and Poly Resin.

- MMA Adhesives: Used for their exceptional bonding properties, enhancing the overall structural integrity – PU adhesives (Bostik)

- Methacrylic Bonding Paste and PU Adhesives: Brands like Bostik were utilised to ensure strong and durable bonds between components – Methacrylic bonding paste.

Key Features

Modular Lightweight Design

The 6×6 Camper boasts a modular, lightweight monocoque design, fully moulded in PET cores. This approach ensures excellent insulation and corrosion resistance and reduces maintenance needs, promising a long service life.

Superior Strength and Durability

The high-strength laminates used in the construction can withstand significant impacts, making the vehicle ideal for challenging off-road conditions. Being made of composite materials ensures no corrosion or rust, provides a long service life with low maintenance, and offers freedom of design, ease of maintenance, and long-term durability and integrity for the vehicle.

Innovative Fabrication

The VIP Infusion fabrication process increased the fibre-to-resin ratios, resulting in improved strength and stiffness of the components while keeping the overall weight low. Additionally, the thermoforming of PET cores enabled efficient styling and reduced the need for further machining.

Unique Features and Additions

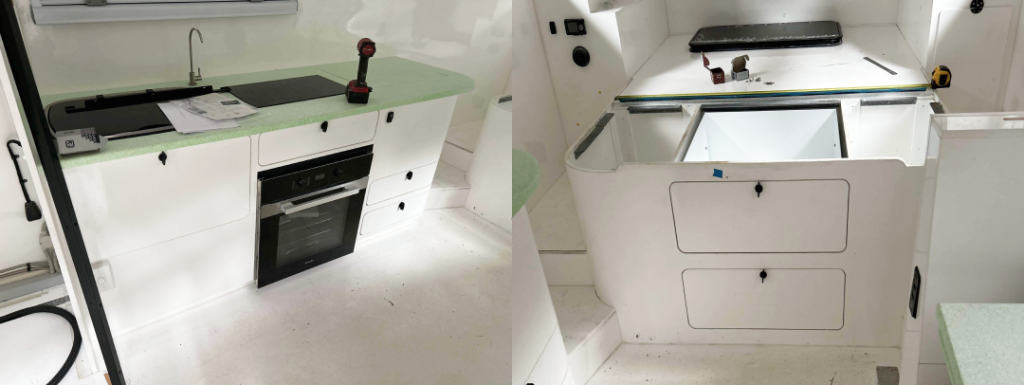

The 6×6 Camper is not just about performance; it’s also about comfort and convenience:

- Laundry Chute and Integrated Laundry System: A built-in laundry chute makes tasks easy and efficient.

- Bike Rack and Storage Solutions: The vehicle includes a winch-operated bike rack and multiple toolboxes for ample storage.

- Advanced Electrical System: The electrical setup, featuring an 8-kilowatt inverter, Victron control system, and LED lighting, ensures seamless off-grid living.

- Water Management: Equipped with a 730-litre freshwater tank, a diesel heater, and an efficient water pump system, the 6×6 Camper is prepared for extended adventures.

Challenges and Solutions

Building in composite materials provided unique opportunities for design freedom and ease of maintenance. The project faced challenges such as integrating various systems (electrical, water, heating) into a cohesive unit, but these were overcome through meticulous planning and expert craftsmanship.

Collaborating Companies and Their Contributions

The 6×6 Camper project was a collaborative effort involving several expert companies, each bringing their unique skills and expertise to the table. FGS Composites spearheaded the project, employing their cutting-edge design techniques to craft the vehicle’s fundamental structure. CFI made a significant contribution by offering top-quality composite materials and delivering expert consultation on the most suitable products to use.

ZWF Maryborough played a crucial role in designing and fabricating the vehicle’s tray, ensuring it was durable and flexible to accommodate heavy machinery. Just A Tip Welding and Fabrication contributed by creating custom under-tray toolboxes and a robust bike rack and implementing the fold-down veranda with aluminium handrails for added convenience.

Loyalty Auto Electrics was responsible for the sophisticated electrical system, installing an 8 kW inverter, LED lighting, and a comprehensive Victron control setup to ensure seamless off-grid functionality. Aqua Gold Consulting provided technical consulting, particularly in refining the interior features like the sliding table and lift-top microwave. Each company’s specialised contributions, including the materials and expertise provided by CFI, were essential in bringing the 6×6 Camper to life, resulting in a unique and highly functional off-road vehicle.

Company Background FGS Composites

The foundation of this project lies in a rich history of expertise and innovation. Our journey began in the exothermic business alongside my father, where I honed my skills in sculpting and building small boats and speciality projects in Europe. After emigrating to Australia, I started out in the bush with tank repairs and boat building.

Moving to the Fraser Coast, I worked in various slipways and factories, eventually establishing my own business as a mobile fibreglass repair service. This business grew, leading to the opening of a dedicated facility for repairing and maintaining grey fleet and fishing vessels. Our operations expanded to include speciality builds such as dome roofing and water park equipment, culminating in the development of extreme off-road campers like the 6×6 Camper.

Summary

The 6×6 Camper by FGS Composites is a testament to what can be achieved with innovative materials and advanced manufacturing techniques. It’s a vehicle designed to withstand the harshest conditions while providing unparalleled comfort and functionality. Whether you’re an off-road enthusiast or someone who appreciates cutting-edge engineering, the 6×6 Camper is a remarkable example of modern automotive design.

Contact Us

Are you ready to elevate your projects with advanced composite technology? At CFI, we specialise in delivering innovative, durable composite solutions tailored to your needs.

Get in touch with us today to discuss your composite needs and discover how we can help bring your vision to life.

CFI – Innovation in every Fibre.

Phone: 07 3040 4353