Products

Composites Fibreglass International provides the industry’s leading raw materials and processing supplies to help you complete your composite projects.

We partner with the best suppliers and resellers in the business to ensure the composites you require are the strongest. View our extensive range of products below, and if you wish to know more you can contact our sales team or visit the suppliers page and click on the link to view their website.

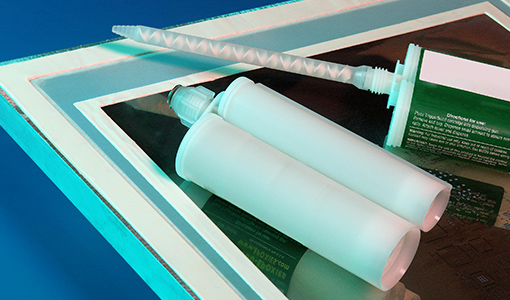

Resins

Resins are a key part of your process and we know that often you need specific characteristics to suit your process, environment, and application.

Gelcoats, Flowcoats & Pigments

Our range of Gelcoats, flowcoats and pigments are specifically formulated to suit specific markets and segments of the industry.

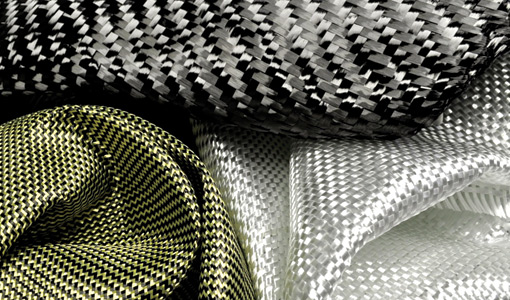

Fibres & Reinforcements

Our range of fibre and reinforcements have you covered!

Core Materials

We are an exclusive supplier of Armacell Cores – the worlds leading core manufacturer in PET structural cores.

Epoxies

Our exclusive Vee-Tek range of epoxy resins, adhesives, casting resins and coatings have been locally manufactured here for over 40 years!

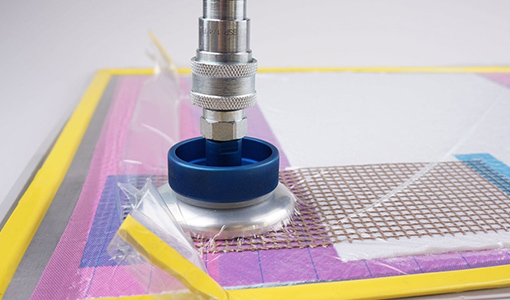

Vacuum Consumables

Our extensive range of vacuum consumables and equipment includes products from the leading European supplier Diatex.

Fillers & Extenders

Our range of fillers and extenders cater for all areas of composites.

Chemicals

We carry a variety of chemicals used in the composites market.

Consumables, Tools & Equipment

Our range of tools and equipment covers many areas of composites.

Adhesives

Need an adhesive? We have a wide range to suit your needs!

Catalyst & Initiators

Our range of Curox catalysts and initiators can be matched to your resin, gelcoat, flowcoat or adhesives requirement!

Specialty Items

We often carry specialty items or can help you source these. If you have a specific requirement, please get in touch with our sales team and see how we can help you.