The Chomarat Group

To read more on Chomarat, please click here.

Construction Reinforcements, Composites Reinforcements and Coatings & Films Textiles

Chomarat is an independent industrial group that was founded in 1898 and has become a touchstone in the world of composite materials and technical textiles. It has three businesses that function in synergy: Construction Reinforcements, Composites Reinforcements and Coatings & Films Textiles. It draws on an international organisational structure with four industrial sites in the United States, Tunisia, France, and China.

The Group has a powerful innovation strategy as it invests in new technologies and fulfils research through academic and technical partnerships on all continents.

Chomarat offers a high level of technical professionals in the most innovative sectors, including the automotive, sports, marine, aeronautics, energy, and construction industries. The market is also demanding high standards, and creativity in industries such as the luxury goods market.

Composites Fibreglass International is an official distributor of Chomarat in Australia. Contact us today for more information.

Chomarat Brands

To read more on Chomarat Brands please click here.

The Chomarat name is associated with leading trademarks recognised as references in the composites world.

A-WEAVE

There are three types of weaves: satin (SA), plain (P), and twill (T) which are all known as A-Weave. It’s a bi-directional aramid woven fabric and creates a better aspect and improved conformability.

ARAMAT

ARAMAT™ is a glass + Kevlar® complex, balanced in both warp and weft, mechanically bonded with a layer of glass fiber. ARAMAT™ is also balanced in volume, as the density of Kevlar® is approximately half of the glass. The brand can be used in a wide range of applications. It has been designed for use in serial production, both in large and small dimensions. Examples include coast guard speedboats, offshore vessels, motor boats, sailboats, catamarans, and trimarans.

Benefits:

- Improves impact strength.

- Substantial reduction in labour (fewer layers).

- Robustness, durability, safety.

- Reduction in overall weight structure compared to conventional glass laminates, aluminium alloy, and steel due to the lower density of Kevlar® (weight reduction of approximately 6% – 12%).

- Excellent compromise between cost and performance.

C-PLY™

C-PLY is a range of multiaxial carbon reinforcements which has been developed using advanced technology and two spreading processes. The brand is comprised of multidirectional and unidirectional stitched piles of 50 gsm to 600 gsm/ply.

Benefits:

- Non-Crimp Fabric has better mechanical properties.

- Optimization of layer construction cost savings.

- Gap-free technology, no resin-rich areas.

Chomarat Solutions – The Widest Offer in Composite Reinforcements

To read more on Chomarat Solutions please click here.

Chomarat has a distinctive range of technologies for designing and manufacturing the widest offer in composite reinforcements. Some composite reinforcements include:

Adhesive Solutions

Chomarat offers two adhesive solutions to help the lay-up of reinforcement in closed mould processes.

- FX: Facilitator of Reinforcements Positioning – FX is an adhesive solution that enables the positioning of Chomarat glass reinforcement products. The key function of FX is to ease the production of large parts with complex geometries in closed mould processes. It is well suited for markets like transportations and marines

- Easytape – Easytape is a range of glass tapes coated on one or both sides. The adhesive solutions maintain reinforcement into the mould and are adapted for bigger parts and complex geometries.

Ballistic Fabrics

Chomarat has a range of ballistic reinforcements that are designed for ballistic protection known as Hard Armour. Numerous fibres can be used, glass or aramid and the choice of fibre is dictated by the level of performance needed: weight, type of threat: bullets, mines, IEDs (Improvised Explosive Devices).

Braids

Braid is a tubular reinforcement that optimises fibres orientation. It offers good deformability and mechanical characteristics by being a continuous reinforcement.

Core Materials

ROVICORE™ is our range of Core Materials. It is a reinforcement made with a synthetic non-woven core and chopped glass fibres mechanically stitched together. It can be used for all Closed mould process requirements.

Advantages:

- Core resilience and compressibility. To adapt to the different thicknesses of parts.

- The high permeability of the synthetic core.

- Adaptable thickness.

- Easy to form in angles and more complex shapes. Time and labour savings.

- Good surface aspect.

- Lack of chemical binder for a good impregnation of the reinforcement.

Flow Media Materials

The range of flow media materials designed by Chomarat aims to ease the resin flow during the infusion process to then replace external flow media. According to the final part properties, various reinforcements are available; however it brings cost-saving benefits and good resin flow.

Needled Multi-Layers

Needled Multi-Layers are a combination of woven roving, stitch-bonded by needling to a mat without chemical bonding. By using the needling methods adds volume to fibres and therefore adds thickness to parts. This range is particularly recommended for the manufacture, with the pultrusion process, of parts requiring mechanical properties.

What Markets do Chomarat Target?

To read more on Markets Chomarat Targets please click here.

Aerospace

To read more on Aerospace please click here.

Advantages of composites in the aircraft industry.

The use of composite materials for aircraft structures is picking up pace. These new materials comprise over 50% of total weight (excluding engines) in the newer long-range airliners. The significant gains in weight and fuel consumption that they allow, have attracted airline companies seeking to reduce cost and CO2 emissions. 33,000 new aircraft are expected to be ordered between 2016 and 2035*.

Chomarat is EN 9100-certified

Chomarat site in China is certified to EN 9100, which is the specific standard required by the aerospace industry. Chomarat continually invests in R&D and in new technologies for its future development in this strategic market.

C-PLY™, a range of high performance multiaxial carbon reinforcements, for composite parts with a competitive edge

Chomarat is strongly active in the development of high-performance composites, and offers a number of innovative products, including its C-PLY™ range (Non-Crimp Fabric technologies), intended for aircraft primary and secondary structure parts or aircraft cabin parts.

C-PLY™ is a multiaxial carbon reinforcement that allows great bending flexibility (up to 20° angles), with regular or very thin plies. Construction can be optimised in the design according to part geometry and load conditions.

These developments open the way for lighter, better performing, and less expensive composite parts, in an aircraft industry where the quest for higher productivity is a major factor.

Automotive

To read more on Automotive please click here.

The automotive industry must innovate and be driven by more progressive goals of regulatory Co2 reductions. By allowing glass, lighter-weighted structures and carbon, continuous fibre composites are an essential part of this transformation.

Chomarat, an organization dedicated to the requirements of automobile manufacturers.

Chomarat composite manufacturing sites in Europe are certified to IATF 16949. Our ability to adapt and develop technologies, and our long-term strategic vision upheld by strong partnerships, have enabled us to become a major player in composites for the automotive industry.

Reinforcements adapted to structural and appearance requirements.

These composite solutions must demonstrate their economic relevance in the face of strong competition from other processes and materials.

Chomarat has been meeting this challenge by offering function-specific structural reinforcements, optimised in weight and orientation, and appearance solutions for the most demanding applications.

With over 50 years of experience in the composite market, the company puts its textile know-how at the service of its customers through high-performance solutions, specifically suited to the requirements of their manufacturing processes:

- Reinforcements for direct processes in closed moulds such as RTM (Resin Transfer Moulding), to meet environmental standards and improve working conditions (by reducing volatile organic compounds, VOCs).

- Function-specific reinforcements based on preforming solutions (powder, fabric, or coated yarn) in order to facilitate their implementation.

- C-WEAVE™ range of optimised woven carbon reinforcements, and C-PLY™ range of NCF multiaxial carbon reinforcements, implementing advanced, high productivity technologies.

- Solutions for high-speed processes, with the G-WEAVE™ range of fabrics and G-PLY™ range of NCF products, dedicated to thermoplastic processes such as organo-sheets or RTM caprolactam.

- Laboratory tools, which allow testing of the behaviour of reinforcements in real-life conditions in the RTM, RTM-L and Infusion processes, and to evaluate critical product and process performance such as permeability or deformability.

Ballistics

To read more on Ballistics please click here.

Chomarat targets composite materials for ballistics due to increasing threats, ensuring the protection of an individual inside a military vehicle. Forming partnerships with their customers, Chomorat has developed reinforcements based on high-performance glass or aramid fibres.

Intended to reduce the weight of armour, these materials improve shatter protection and therefore meet the safety constraints in military and civilian applications. Chomarat, in collaboration with DuPont®, combines a Kevlar® fibre-based reinforcement with thermoplastic film as a solution. This transformation is an alternative to traditional solutions, i.e offering ease of implementation, reinforcements combined with phenolic resins, without emission of VOCs.

Energy

To read more on Energy please click here.

Wind power, a growing world market

The wind power industry continues its growth, with 55 GW installed during the year 2016. This trend can be explained by two factors, environmental considerations and economics.

The COP21 agreements have created new growth opportunities for clean energy solutions such as wind power. China, India and the United States, among others, have increased their investments in this area; as a result, the global cumulative capacity is expected to reach 2000 GW in 2030, compared to 500 GW at the end of 2016. Concurrently, thanks to its sharply declining cost, wind energy is becoming a competitive alternative to fossil fuels.

Cost reduction, however, remains a challenge for this industry. The increase in turbine performance and the development of offshore technology (sea-based wind power) have contributed to reducing costs. These changes have created new structural constraints for wind turbine blades, which must withstand extreme weather conditions. The size of these blades is constantly increasing (now in excess of 80 meters) while an optimal weight/power ratio must be maintained.

To accompany the advances in this industry, which is constantly looking to optimise its materials and processes, Chomarat has developed new textile solutions for composites.

The work carried out in collaboration with Professors Stephen W. Tsai of Stanford University and Sung Ha of the University of Hanyang, have shown that blade design could be optimised in terms of weight, performance and cost, through the use of multiaxial reinforcements (NCF) based on fibreglass (G-PLY™) and/or carbon (C-PLY™).

Using the G-FLOW™ range of structural and vacuum-draw systems developed by Chomarat, results in shorter blade manufacturing time while lowering cost by about 13% compared to an external flow medium.

Chomarat is a worldwide industrial presence.

The implantation of Chomarat in Europe, China, Tunisia and the United States guarantees our customers a competitive, high-quality global offer.

Industrial investments made in recent years, particularly in its production capabilities for multiaxial reinforcements, demonstrate Chomarat’s commitment in these high volume markets.

The challenges of the oil and gas industry

Another alternative for meeting our energy needs is to drill deeper and deeper into the ocean floor to extract fossil fuels.

This requires designing new flexible tubing, capable of withstanding the high pressures and extreme conditions found inside a well at depths of 3000 meters. Chomarat is meeting these challenges by creating special reinforcements which combine technological know-how and high performance fibres (aramid, carbon, etc).

Industry

To read more on Industry please click here.

Dedicated to reinforcement industrial applications, the overall performance of their corrosion resistance, durability, and lightweight properties, composites are particularly popular in this market. Chomarat designed a wide variety of reinforcements including braids, complex, fabrics, ribbons, and multiaxial reinforcements which can meet the full range of needs in the industry.

Chomarat offers high-performance solutions in areas such as trenchless pipe rehabilitation, corrosion prevention, electrical or gas cabinets, and more.

Visit the Chomarat Pipe Relining Product Sheet.

Visit the Chomarat Pultrusion Product Sheet.

Marine

To read more on Marine please click here.

Chomarat is a leader in the marine industry.

Chomarat develops glass, carbon and aramid-based reinforcements, using various conversion processes (weaving, multiaxial, combining, etc.), in order to meet the expectations and requirements of the recreational, racing, fishing and military boat markets: weight reduction, better surface appearance and stronger structures.

Chomarat also assists its customers in improving their own production processes (i.e., transition from open-mould processes to closed mould processes), thanks to its reinforcements which can assist resin flow or combine vacuum-draw and structural functions:

- Glass (G-PLY™) and carbon (C-PLY™) multiaxial reinforcements for better rigidity and lower weight of parts.

- Expertise and tools serving the shipbuilding industry

- Fabrics.

- Reinforcements for infusion process: G-FLOW™, a 100% glass structural and vacuum-draw system, ROVIFLOW™, a laminate combining a reinforcement and a glass or polyester vacuum-draw system.

- Glass and carbon UD composites.

- Reinforcements based on Kevlar® fibres for shock resistance, suitable for high speed military vessels (fast patrol boats).

- The company assists its customers in the design of reinforcements and selection of materials, supported by an in-house composites laboratory. Equipped with state-of-the-art instruments, it allows us to measure and simulate the permeability of reinforcements and structures, as well as the mechanical properties and surface appearance quality of the finished parts.

- The ROVICORE™ range, intended for the RTM Light process.

Chomarat is certified DNV GL for its ranges of glass and carbon multiaxial and tapes products, marketed under the G-PLY™ , C-PLY™, C-TAPE™ and G-TAPE™ brands. These certifications are a token of craftsmanship and quality.

Sports Equipment

To read more on Sports Equipment please click here.

Chomarat is an historical actor in the sporting equipment market.

The company was one of the very first players to participate in the development of composites for skis. Exceptional know-how in ribbon weaving is one of its many assets. The flexibility of this technology is particularly well suited to the ski manufacturing process. It allows production of narrow widths with a preferential axis at 0°, using a wide variety of materials (glass, carbon, aramid, basalt, natural fibres, etc.). Ribbons have the particularity of combining technical function with aesthetics.

Chomarat also uses multiaxial technologies, widely praised by ski manufacturers. Available in various constructions (biaxial or triaxial), these NCF reinforcements can be combined with fabrics, cut into strips, and made from different fibres.

Combining design and structure.

More recently, Chomarat has developed C-WEAVE Design, a range of carbon fabrics combining original design and structural performance: 100% carbon reinforcement, or carbon/Innegra™ hybrid reinforcement, providing shock resistance and vibration damping, particularly appreciated in sporting equipment.

With C-WEAVE Design, Chomarat has broadened its offer to include products for premium quality appearance, intended for demanding markets. The size of the design is particularly tailored for large parts such as surf boards or hydrofoils.

Innovative reinforcements for winter sports.

The sporting equipment industry is constantly searching for ways to optimise its processes and the quality of its products. In order to meet the accompanying demand, Chomarat has developed C-PLY™, a range of carbon-based multiaxial reinforcements (NCF).

Close collaboration with Steve W. Tsai, Professor Emeritus at the University of Stanford, has led to the development of C-PLY™ for tight angles (20 to 30 degrees). This patented, fully innovative reinforcement has allowed us to improve the fatigue resistance and lower the weight of parts with preferential direction such as skis, for better control of dynamics and behaviour on different types of snow.

The performance of Chomarat reinforcements has also proved useful for tubular structures such as bike frames, for which the stiffness/weight ratio of each tube section must be calculated and optimised. Fabric or multiaxial is then selected based on fibre orientation, but also on the required final appearance.

Innovation, at the heart of the Chomarat strategy.

The Chomarat Group participates in the I-COMP Sport applied research consortium, whose studies are hosted in Singapore at the Institute for Sports Research, in the prestigious Nanyang Technological University.

One of the developments, conducted jointly by Chomarat and the ISR, demonstrates the possibility of using an automated technology which combines RTM and dry, preformed shapes to produce a high performance racquet prototype. This technique, combined with optimised reinforcements, is an alternative to conventional pre-impregnated technologies, thereby reducing human error while guaranteeing consistent quality.

Transportation

To read more on Transportation please click here.

Composites in the railway industry.

Thanks to their useful properties, composite materials have become indispensable in the railway construction market. They provide weight reduction (which reduces track wear and increases transport capacity), corrosion resistance (which lowers maintenance requirements), and functional integration.

Railway parts must also meet European standards for fire/smoke resistance (EN 45545). In this context, Chomarat has developed ROVICORE™ FR (Fire Resistant), a sandwich reinforcement based on glass fibres. Used in mould processes and combined with suitable resins and gelcoats, ROVICORE™ FR is the proven solution for manufacturing composite parts that comply with fire and smoke standards.

Composites in industrial vehicles (buses, trucks, farm equipment).

Just like light vehicles, industrial vehicles must meet CO2 emissions regulations. Given this new legislation, combined with a desire to lower energy costs, weight reduction has become a major axis of development for manufacturers.

In this context, composites offer new alternatives to metals, by providing strength and lightweight properties.

Chomarat has been serving the bus and truck market for several years. It has developed a range of woven fabrics, G-WEAVE, and laminates that meet manufacturers’ requirements for structural parts and refrigerated truck panels.

With its Rovicore™ range, intended for closed-mould processes (RTM, RTM Light, etc.), Chomarat is able to comply with changing environmental standards (reduction of VOCs) and with the quality, consistency and productivity requirements of its customers. Rovicore™ is specifically used for manufacturing hoods, roof risers, spoilers, etc.

Chomarat Success Stories

To read more on Chomarat Success Stories, please click here.

C-PLY™ in Arcona cruisers-racers 435 and 465

With many years of expertise, Chomarat is a pioneer in crafting solutions to achieve weight reduction, stronger structure and improved surface appearance. C-PLY™ enables these specifications to e met, while ensuring cost-effectiveness and stable quality.

A study was carried out to determine the optimal construction to develop a high performing C-PLY™ range for improved permeability in infusion process. The result is a carbon NCF that achieves high mechanical performances, multi resins compatibility and cost efficiency.

C-PLY™: lightweight and strength for marine applications.

C-PLY™ reinforcement is applied to the hull and deck of Arcona 435 and 465. Both cruiser-racers are a unique combination of performance and comfort onboard, for fast family cruising and high-level races thanks to their specific design, and the use of C-PLY™.

The Arcona 435 model even won the highly regarded award of European Yacht of The Year in 2019, in the Performance Cruiser class. The carbon construction makes it possible as we get a lighter, stiffer and managing calculated loads on higher levels than glass fibres. C-PLY™ is essential to achieve the calculated strength without adding extra weight or thickness to the laminate. It gives a cost-effective solution in production as reaching a high strength with fewer layers.

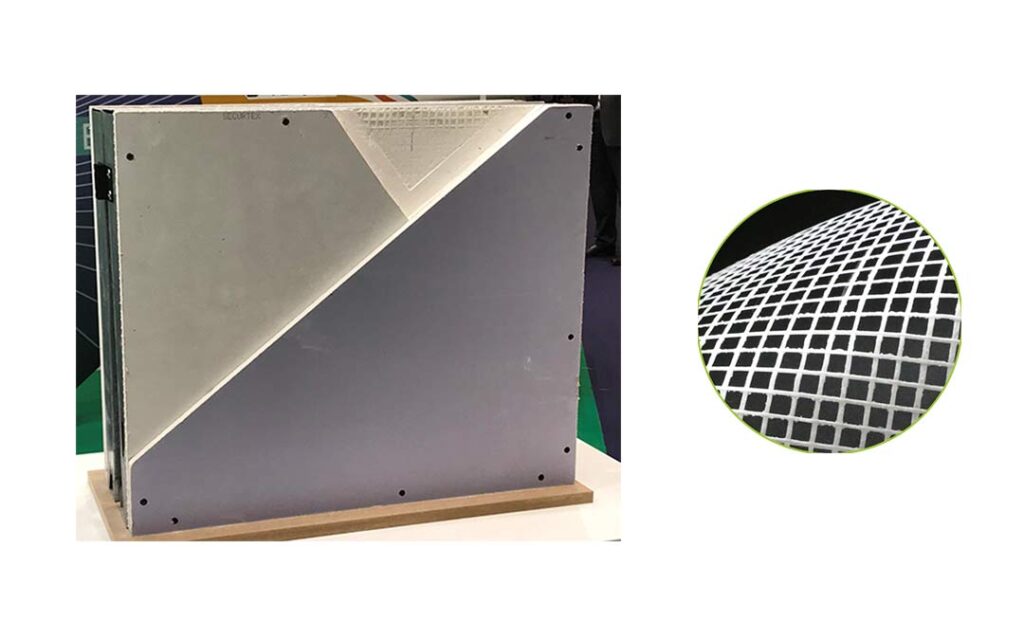

ROTATEX™ reinforces Siniat Securtex® attack-resistant plasterboard

Securtex®: anti-intruder walling system.

Siniat Securtex® plasterboard contains a laid high-tensile glass scrim from Chomarat, fused with a dense gypsum core.

Rotatex, laid glass scrim, brings additional mechanical strength and dissipates the force across the entire area of the board, providing impact resistance to party walls and door sets.

No other components, such as metal lath or ply in the partition, are required in the system to design out crime and help avoid long-term maintenance costs caused by damage.

Taking advantages of Chomarat experience both in textile & chemistry.

Rotatex™ laid glass scrim used in Securtex® was developed in close collaboration with Siniat: this glass grid is specially designed to provide:

- Good tensile strength and tear resistance.

- The Chomarat coating contributes to the flexibility of the grid and offers excellent resistance to puncture and ageing.

- The diameter of the threads is selected to craft a grid with considerable mechanical properties and flexibility.

C-PLY™ Hexagonal : at the heart of Babolat’s new tennis racket “Pure Aero”

In 2019, the Pure Aero presents high spin through a clever mix of two innovative concepts, resulting from ambitious technical partnerships:

- C-PLY™ developed by Chomarat for superior stability

- Cortex Pure Feel developed by SMAC for exceptional feel

Extraordinary stability and incredible feel.

The addition of Chomarat’s C-PLY™ Hexagonal multiaxial carbon reinforcement at the heart of the Babolat Pure Aero racket boosts performances and enhances stability. The C-PLY™ Hexagonal fibre presents additional stiffening and an exceptional design. This unique fibre holds the colour of resin pigments, as it has been tailored to remain visible after impregnation.

C-PLY™ Hexagonal is one of the first multiaxial fibres to be applied to a racket; it is pre-impregnated and then processed without any modification in the manufacturing process. This reinforcement replaces the UD prepreg traditionally used in this type of process. Integrated in the throat of the racket to give the new Pure Aero amazing stability, this carbon reinforcement is more rigid, allowing more stability at impact, which enhances control.

Want More Information On Chomarat?

For more information on Chomarat’s brands, solutions and who they target in the market, feel free to visit their website.