Spring is here and after a long cold winter with relentless rain, and La Nina it seems it’s still not back to normal as we are used to here in Sunny Queensland. Perhaps Covid has attacked our weather as well. In this newsletter we would like to update you on our latest additions to our range of raw materials. In our main article we touch on the boat builders of Cairns, Tropical North Queensland and some of the local talent around the traps. We also have a look at the market and what the outlook may look like moving forward.

Overview

Welcome to our spring newsletter and I hope this finds you well. It seems that for the last couple of years we have learned to live with the uncertainty of Covid. We never really know what it is next and how it will affect us. Still, there is always a surprise that you didn’t expect. It may be not necessarily a direct effect of Covid, but a work that now seems not as stable or cohesive as it once was.

While living with Covid has become less of a constraint with moving around and travelling here in Australia, and abroad to some extent, the impact on us all is seen to affect us in various different ways. Things like shipping delays around the world, a lack of raw materials at times or long lead times in manufacturing, and country to country, it seems to be labour or skills shortages that all add up to big delays.

Throw in a war between Ukraine and Russia and the knock-on effect to energy supply to Europe, it presents a new crippling effect to European countries and the industries and plants that rely on products like gas and food to keep them running. With the onset of winter just around the corner, the race is on to fire up alternative energy suppliers to keep people employed and manufacturers producing in many parts of Europe.

Don’t forget that China now also looms as a major threat to stability in the Pacific and is posturing to make moves on Taiwan. Additionally, it’s actively violating territorial waters and airspace over what it claims to be their own, resulting in bullying and harassment on a large scale. Then there’s the wild card of Kim in the North with his Rockets. He also wants attention. Seems to me we are going back to the bad old days.

The new government here is settling in and has its own challenges to bring inflation under control. The standard method of raising interest rates always hurts the small side of town quickly. Now with five upwards increases in the cash rate, it is noticeable in the reduction of orders and spending notes for many of our customers. But on the other side – while interest rates rise and house prices start to stabilise and drop off here and there, it creates a new challenge for the Federal Government as export sales increase and are looking good with Europe. Others need to include plenty of fossil fuel such as coal and exports like wheat to keep Europe running and fed.

Maybe a lesson can be learned here. You can’t export solar or wind energy, and you should not put all your eggs in one basket. So, while we adapt to the next set of challenges, things still don’t look too bad now, but it is strongly advised that we could by mid next year get very close to a recession. Cash flow will be important for all businesses and reductions in spends or delaying investments where possible will be wise if they can be reduced or put back without impact to daily business and operations.

It’s not all doom and gloom as there is still plenty of work to be done and forward orders are still there for many. With the Olympics a few years down the track for Queensland, this normally brings a steady flow of government expenditure and projects that help to stimulate the economy. So it’s anyone’s guess these days as to how things will pan out, but it’s largely up to ourselves to read this as best we can and be prepared for whatever ride it is.

Around the Traps

Boat builders of Cairns

For decades now Cairns has been world famous for the heavy tackle fishery for the giant blue, black and striped marlin along with many exotic reef fish.

The Cock & Bull Pub

Located in Cairns, home of the Cairns Game fish Club, great meal no matter what you choose, and the beer is pretty good as well.

The Cock & Bull Pub – Located in Cairns

Cairns Boating & Fishing

Since the fishery was established, the region has had a long history of boat building for both pleasure and commercial fishing. The game fishery first kicked off in 1935 and was in its prime up until 1979. It continues today with a well-managed charter for all that want to fish this amazing place at some point in their life.

While the town has slowed down from the hay days, it still supports a passionate bunch of builders who keep the boats running, as well as build new boats and, in many cases, have had a long and famous history with this world heritage listed town.

My time in Cairns goes back many years to another life. I looked after the region for FGI. During that time, I met many of the legendary game boat builders, skippers and deckies. Some who have passed and some I still look forward to meeting every time I visit on my sales trips. I have forged a close and personal relationship with many I call dear friends and with what was my home for some years amongst the many people of Cairns.

Dick Ward – Master Tradesmen in Timber Boat Building

I start off the piece with an introduction of Dick Ward. I put Dick as a mentor to myself and one of the locals who took me under his wing from day one, and to these days continues with his wife Margie still to be one of my best mates in the region. Dick is now retired and is one of the legends of the game boat building history of cairns. During my time I built several famous game boats such as the Kanahoe, Tradition and the Pocket Express boats called the Pirates just to name a few.

Dick, a master tradesman in timber boat building, quickly adapted to advanced materials during my time and built his boats in epoxy foam sandwich vacuum bagged technology. His boats still are highly sought after if you can get your hands on one.

The Nakara is a 60ft Halvorsen Vessel

Col Feature here with his apprentice Brent are epoxy sheaving this old 1947 built Halvorsen cruising vessel, The Nakara. Col himself has a fully restored old fishing vessel which he and his wife often seek out to the reef on for the weekend. Col is a wealth of knowledge and he is always happy to pass on his knowledge and help to anyone who needs some advice and/or materials. He also has a steady stream of work through his shed for the local fisherman and recreational boaties.

Joe Woo here is epoxy sheaving the Nakara.

Traditionally built carvel planked boats such as the Halvorsen pictured here require a certain set of skills to replace planking and make this watertight again. I found old Joe Woo (the one trying to hide his good looks). I first met Joe many years ago when I was here in Brisbane working with Barry Martin at Assegai. Now I often find him under one of the old Pearling luggers or a classic old timber boat fixing rotten, worm eaten planking or caulking a seam.

1947 Halvorsen Cruising Vessel – The Nakara

It’s good to see here that many of the skills a boat builder once needed to learn in order to build a boat are still present. Nowadays, these skills are dying out as our old mates pack away the tool bag and carry it all away. Let’s hope some of these skills and knowledge gets passed on to the younger ones before we lose the know-how.

Rob Storer (Lifestyle Marine Cairns), with son Josh and apprentice Jet.

Lifestyle Marine Cairns – Rob Storer

One thing you learn when you go to Cairns is there are locals and there are people just passing through. To be a local is still a question of how long, but for sure Rob is a local. When I talked to him on my last trip, I asked Rob how and when he got into the boat building game.

“It’s a long and funny story” he told me. Working as a Cabinet Maker by trade, Rob had been making cabinets for fit outs for one of his customers, Manta Craft that once was a flourishing catamaran builder in Cairns in the late 80s.

Typical of boat building schedules, Rob would get a call up to come and install his cabinets and trims on a new build, only to turn up and find what he was fitting up against such as a bulkhead, floor or framework had not yet been built into the boat. After a while Rob ended up doing this work to finish his work he had prepared. Hence, he got sticky and learned the FRP fabrication side of boat building.

Eventually this led to where he is today, running his own business – building, refitting and repairing fishing boats for professional fisherman in the North as well as locals needing a rebuild or repairs. Rob has a small crew that includes his son Josh and apprentice Jet. Rob had been an advocate of supporting and training the young guys and seeing them through their training with the support of Partech.

Being one of the few still doing the work around the town, he has no shortage of work. He is known for tuning out better work than when the boat may have first been built. An important point Rob raises is that people don’t just go for a fish in the river here. Additionally, there are things that are a bit hard in the waters, so you want to be sure that if you go out you will be able to get back in a reliable, well-built boat.

Newly formed Marino Boatworks has just hit the ground running.

Marino Boatworks

Newly formed Marino Boatworks has just hit the ground running as I visited last trip. Tom Tembath is new to boat building and has spent a lot of time over the past few years doing his research into two new designs for high-end trailable centre console builds.

Tom has had renowned naval architect firm Michael Peters Design from the USA design his boats. Michael is well known in the area of performance hull forms and is a master at the stepped hull design. Both of Tom’s builds carry the signature hull step.

The tooling has been CNC milled and the first hull is underway. Made from cored sandwich construction in the VIP process. Composites Fibreglass International have been working with Tom and his team (Josh and apprentice Brayden) and with the local support of Col Wheatly and Mark Halford of Partech. We are helping Tom to get up to speed as quickly as he can.

Tom has a young and energetic crew of two that are willing to listen and take on board the enormous number of skills and learning ahead. We wish them all well and look forward to seeing their new range of sports fishing boats develop. The first hull is now out of the mould and orders are coming. We are very pleased to see some new young talent in Cairns.

There are many more I could mention but we would run out of time. Another one of the famous families in the Australian boat building world is the Lacco’s. Some of you may know the name from Melbourne. Famous for the couta boats, Ryan Lacco is also situated in Cairns and is the builder of the Cyclone Racing ski boats, as well as doing a lot of work for the naval yard here in Portsmouth. On a brief visit to catch up with Ryan I noted what looked very much like a modern strip planked couta boat being built in his shed. Much to my surprise, the man building this hull was Rod Lacco (Ryan’s Father).

Rod also during my years in Cairns built many game boats and fishing boats and at one time fished for Mackerel. Rod told me he had retired but daytime television is effortless, so building a boat is a much better way to pass the time. I tend to agree and it’s great to see another master going on about his craft effortlessly.

Further Afield

As we talk about boat building and young guns, I just had to include one from down south here on the Gold Coast – Assegai Marine. This also was a name synonymous with the building of high-end game boats here in Australia. Owner and builder Barry Martin only just a few years ago packed up shop and was contemplating retirement – much to the horror of anyone who still hoped one day he could build a boat for them.

Craig Martin (left) with best friend and co-worker Troy (right) – Assegai Marine Gold Coast

Like any of these guys they don’t seem to warm to daytime TV and find themselves back at the drawing board. Lucky for Barry, his son Craig Martin had also found moving on to other work not as much of a challenge, or at least not as fine as building a high-end custom one-off boat. Craig is now taken on the Assegai Marine name and brand and with his best friend and co-worker Troy. They are back at the old shed and building a brand new fully custom 30ft vessel, while Barry watches on and does the design work.

I guess I would have to say if you are trained and work under a Master craftsman then you will be well skilled. And I would have to say that Craig and Troy are really in this class of Master Tradesmen and craftsmen. Their work is effortless and second to none. The build is coming along nicely, and you can see the level of details and skills in the set out of this build. Our trade is in good hands with this lot.

Hull is strip planked in PVC core and glassed internally. Bearers and transverse framing along with bulkheads are fitted and glassed. These are of armacell PET core.

The hull is then rolled to glass and fair the outside before being turned back to have the deck and cabin fitted.

What’s New At CFI

CFI is pleased to announce the Australian distribution of Alan Harper Composites Silicon bagging technology. Composites Fibreglass International will carry a range of products and equipment to implement the use of reusable close moulding vacuum bags for LRTM processing. To learn more please contact us directly to discuss your needs.

CFI has just landed its first shipment of Chomarat Carbon fibre fabrics. Chomarat is a specialist weaver of Carbon fibres and other glass fabrics and products. CFI are carrying plain weaves, twills, double bias, quadaxial as well as unidirectional fibres all in carbon fibre. These are high quality, including weave set finishes for detailed lamination work.

Our first rolls of FRP high glass gelcoat FRP skins are arriving now from Polser. Polser make a variety of grades, colours and finishes and we can offer you the very best quality in FRP skins in varying widths and thickness. To learn more, contact our office directly or visit Polser.

CFI now supplies PVC cores directly to the market. We carry a range of thickness and densities and bring in any density, thickness and finish you may require.

Our range is DNV/GL certified. Densities from 45kg/m3 to 250kg/m3. To learn more, contact our office.

CFI are now seeing a strong demand for finish coating of plug work and finishing of high-end carbon work where a clear coat is needed. See data on primecoat here and cystic gloss coat here.

The Scott Bader Cystic Primecoat and Clearcoat are perfect for this work saving time and giving an excellent glass finish. These are extremely cost-effective when compared to other imported coatings and use M200 MEKP as the catalyst. In the case of thinking, MEK solvent is recommended. Call us to learn more on how to work with the range.

Keeping Your Hand In

At CFI we believe that reps should not only have product knowledge, but should have a good understanding of how to use and get the best from the products.

We can report that our team is always in the shed trying out resins and gelcoats, or with our customers performing a spray up and even teaching or giving a demo.

We also have some members of staff internally who once wheeled a mighty Chopper gun and have a good understanding of FRP fabrication and can talk to you about this.

For myself, I find I can’t help but keep my hand in on my latest project. As this addition of the newsletter was dedicated to the Cairns region, I thought it would be fitting to let you know that one of the past legends of Cairns’ heavy tackle game boat building Frank Woodnut was a builder I met many times during my work in Cairns. At the time of meeting Frank, I had to demonstrate my capabilities as well as show my materials were worth his use.

For some months while he was building the Cairns coast guard boat, Frank would request that I arrive before 2.30pm each afternoon to assist Mario and Dario; two Innisfail Italian brothers and himself to laminate the hull of his new build in Epoxy resin. The time was set to 2.30pm as the call to the local post office reported the humidity was low enough to meet survey requirements. This meant a drive each day to Innisfail and then a late drive home at night.

Over this time, I learned both Frank and I had served our time as apprentices at Halvorsen boat builders in Sydney (some years apart of course). Now after many years, Frank joined Noah in the big shed up top. I have the privilege of restoring the 1972 Townsville Fisheries boat he built, Rigel.

This is keeps my hand in on the weekends, and I try to bring the old girl back to life. Here are a few pictures of the journey so far.

The Rigel after we trucked it down from Cairns where it sat for about 10 years in a shed half pulled apart.

A quick dry fit of the new Cumins 6BT diesel motor to check it would get in. The old boat had a 6 cylinder GM that is now long gone.

Restoring the 1972 Townsville Fisheries boat – The Rigel. Still a long way to go, but it’s all good fun.

Restoring the 1972 Townsville Fisheries boat – The Rigel. Still a long way to go, but it’s all good fun.

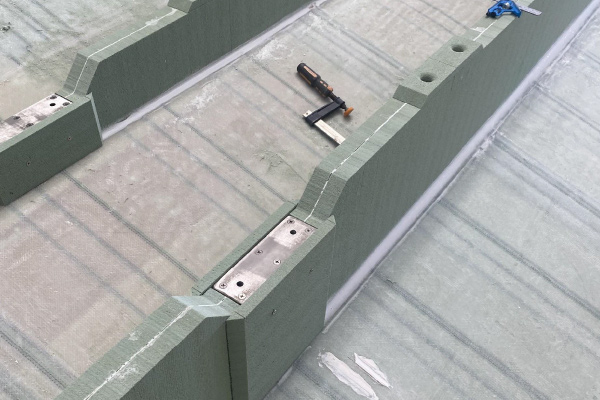

New gunwales fitted and shaped replace the old rotted ones. These are our GR320 Armacell Pet glass over with two layers of 600-gram Double bias.

Alan Harper Composites

Alan Harper Composites Ltd. is a specialist closed moulding technology innovation and production house. Offering business to business revolutionary composite production advances while providing the closed mould and composite plastics fraternity with the world’s most cost-effective and efficient technology. We have designed and produced a world class reusable silicone membrane closed moulding system that permanently removes the need for costly and environmentally unsound use and disposal of one-time-use composite consumable membranes and waste.

fiRST – Fibre Infusion Reusable Silicone Technology

The fiRST system provides the more cost-effective solution to infusion moulding by employing reusable membranes, which replace consumable films and incorporate many other infusion film requirements including seals, resin feed channels and vacuum porting into the reusable fiRST membrane (vacuum bag).

Specialties

fiRST – revolutionary reusable silicone vacuum membrane technology, SilCon spray machine solutions, vacuum pumps, embedded heating, embedded breather, unique hidden resin runner systems. On site training, high quality approved platinum silicone supply and additives.

SilCon

Our SilCon machine range offers economic silicone film spray solutions which are entirely air operated and boast almost zero maintenance requirements . We also provide a full range of unique silicone membrane ancillaries to equip the mould builder with every building block specifically designed for this new reusable membrane production technique.