Sphere.skin

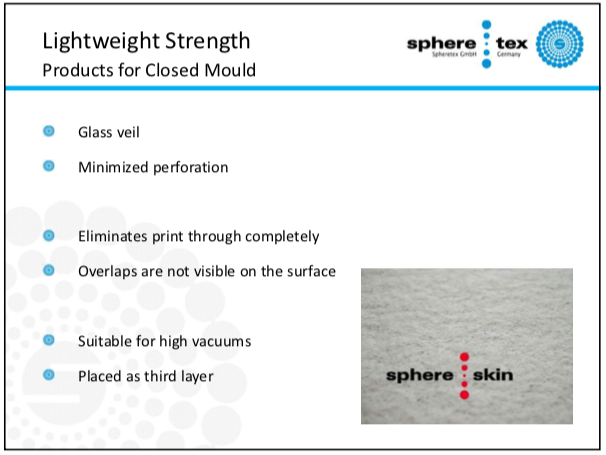

Sphere.skin is a glass fiber based product that is volumised by thermoplastic microspheres. It is designed as surface improvement layer to greatly enhance the surface quality of the molded part.

Sphere.skin is laid up in dry form behind the Gelcoat and a tie layer. The tie layer, either a barrier coat or a light chopped strand mat (Skincoat), is protecting the thermoplastic microspheres and to ensure a sufficient impregnation and bond to the Gelcoat.

Sphere.skin is available with a stitch bonded layer of CSM: Sphere.skin Complex.

Sphere.skin HT is especially designed for the use with Epoxy resin and a vacuum up to 0,85 bar.

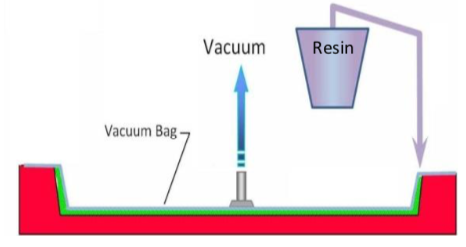

Infusion (VIP)

Sphere.skin performs excellently within infusion process. Since stretchable film is used as counter mold and thus the laminate can increase in thickness by about 0,9 mm. While applying the recommended vacuum of 0,6 bar Sphere.skin 1,3 mm is compressed roughly by 30 %.

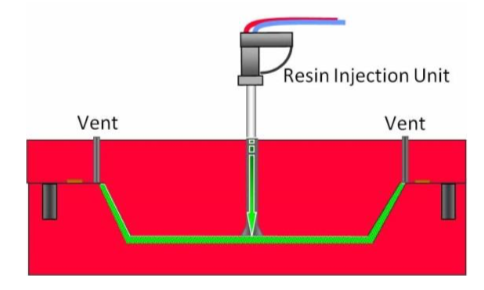

RTM – RTM light

While applying Sphere.skin the mold cavity depth needs to be adjusted to account for the increased layup. Otherwise the additional material will lead to a over compression of the inserted layers. The result can be a decreased resin flow which can lead to dry spots in the laminate.

PAN veil

For RTM or RTM light a PAN veil is the best solution. It won’t affect the cavity of the mold.

The PAN tissue can also be stitched directly onto Flowmat or Sphere.mat C IP. The stitching is not visible on the surface of the laminate. Further the inserting of only one complex will decrease the processing time.